Automatic Vertical Edible Salt Pouch Sachet Filling Packing Machine

We are leading manufacturer of salt pouch packing machine. It can be used for ediable salt, industrial salt on the road, dishwasher salt,nasal rinse salt etc. SHUNTIAN can meet these needs of customers. This automated salt bag device system belongs to the small pouch packing machine.We have two series:salt sachet packaging machine,salt pouch packing machine.

- Material Type: powder

- Packaging Material: film

- Max Packing Range: 5 kg

- Min Order: 1 set

- FOB Price: 2900 USD-28900 USD

0086 139 2007 7206(Mobile)

Check out the following video on different kinds of salt packing machine

fl type vertical powder packing machine

fl type vertical granule weighting packing machine

This high quality automatic salt powder packaging and filling machinery can realize fully automatic loading, weighing, bag making, filling, sealing, bag opening cutting and finished product conveying in one, which can pack bulk materials into small packages with high added value of fixed weight forming. The packaging speed is fast and the operation is stable. The salt packing machine is widely used in the packaging of cereal products such as rice and grains and powder such as coffee in small bags, suitable for mass production, with beautiful bag shape and good sealing effect, easy for boxing, crating or direct retailing.

Feature for ediable salt packaging machine:

1.Ideal for pepper,salt granule, turmeric etc.

2.Options for mechanical and pneumatic type sealing

3.Film:Laminated PE film, aluminum foil poly, aluminized film

4.Variants pyramid pack and premade pack is available

5.It can pack 5g-5kg

Low maintenance and low operating cost.

Technical Parameters for salt packaging machine:

| Model | DXD- 100H | DXD- 500H | DXD- 800H |

| Sealing | Back/3 sides | Back/3 sides | Back/3 sides |

| Packing speed(bags/ min) | 20-60 | 20-60 | 20-50 |

| Bag size(mm) | L50-170

W50- 120 |

L50- -200

W50-150 |

L50- 200

W50- 280 |

| Filling range(ml) | 10- 100 | 100- 500 | 100-800 |

| Power(v/kw) | 220V/1 .8KW | 220V/1 .8KW | 220V/1 .8KW |

| Weight(kg) | 300KG | 350KG | 400KG |

| Dimension (mm) | 790*600* 1780 | 1300*930*1850 | 1300*1080*2100 |

Advantage of salt powder filling machine

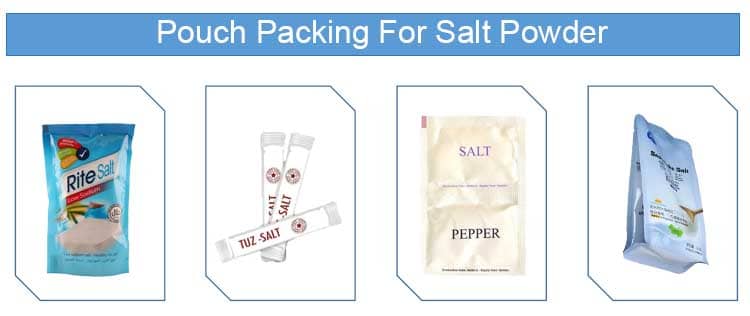

1. The bag can be made into stick, sachet or pouch type

2. The machine is guaranteed for years and is repaired for life. Most of the components are from Germany, and the PLC touch screen is from Siemens. This high-quality component makes the machine basically non-faulty.

3. This kind of machine is more intelligent. It can produce not only salt but also pepper. Our twin bag machine is very famous and it is widely used in aviation and other fields.

4. Our salt bag packaging machine can punch holes, print dates, etc.

5. The weight error is controlled within 1%.

Packaging principle of ediable salt vertical packaging machine:

Place the roll material of the salt bag, such as PE film, laminated film, etc. on the top of the machine, place the salt in the screw or measuring cup, use the bag maker to make the roll material into a shaped packaging bag, and then perform filling, packaging, sealing, etc.

What should you consider before buying salt sachet packing machine?

The benefits of a salt stick packing machine cannot be emphasized enough. These machines are designed with several functions and parts. You should buy one that is suited for the type of production you are planning to do.

The following are some factors to consider when buying a machine. The size and functionality of the sachet packaging machine should be taken into account.

The sugar stick packaging machine has several features. 1. feature is the filling device. This machine uses volumetric measuring devices to fill the sugar into the sachets. 2. feature is the multi-track filler, which automatically transfers the materials into the sachets.

A single-lane sugar stick packing machinery forms a single long pack that can be divided into several sizes. If you are only making a few packs a day and want to keep the cost of the packaging low, you can choose a single-lane version.

Many companies hire them instead of buying them, especially if their packaging requirements are minimal. The safety features of the machine are an integral part of the overall package. Whether it’s a new machine or an older one, there should be a set of instructions and safety gear for the operators. Then, you can decide which model to purchase.

SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN

SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN