- ST-LT500 handle box bag non woven making machine

- ST-AS400 T-shirt bag non-woven bag making machine

- ST-A700 W-cut bag non-woven bag making machine

- ST-B700 flat pocket bag non-woven making machine

- ST-C700 multifunctional non-woven three-dimensional bag making machine

- ST-D700 Flat mouth ironing non-woven bag making machine

- ST-E700 Three-dimensional ironing handle non-woven bag making machine

- ST-B700 Non-woven fruit bag making machine

- ST-H700 Automatic non-woven zipper bag making machine

- ST-350 Non-woven bag making machine for Chinese medicine bag, tea bag, seedling bag

- ST-500 vest bag non-woven bag making machine

D Cut And W Cut Non-Woven Fabrics Bag Making Machine

We are manufacturer of D cut And vest cut automatic non-woven fabric bag making machine in China. The carry bag is used for shopping, supermarket, loop handle, if you are looking for punching machine supplier, please contact us.

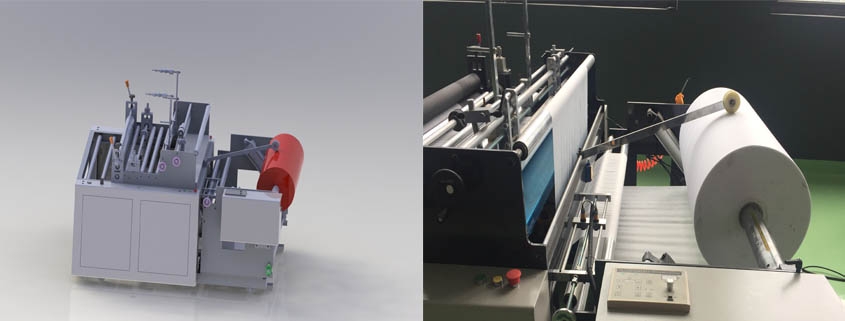

W-cut and D-cut bag non-woven bag making machine

- Origin:China

- Model NO.: ST-A700

- Bag type: W-cut, D-cut

- Price terms: FOB, CIF, CFR

- Payment terms: T/T, L/C

- Min order: 1 set

This fabric non woven is advanced in technology, stable in operation performance and fast in bag making. It is one of the most advanced non-woven bag making machines in the world.

The machine is used for raw materials, non-woven fabrics, can process a variety of different specifications, different shapes of non-woven bag, flat bag, vest bag, the electromechanical machine is set as a whole, the use of LCD touch screen operation, step with fixed length, photoelectric tracking, automatic positioning computer, computer automatic correction. Accurate and stable, and can set automatic counting, counting alarm, automatic punching and other industrial equipment, the production of finished sealing strong, beautiful tangent. High efficiency, high quality is environmental protection equipment bag you can be assured to use.

Process flow:

Roll material — side folding — heat –cross folding — insert — Position — punch — heat — cut — collect the finished product — automatically press into vest bags.

Main Technical Variables:

| Type | ZXL-A700 |

| Material Width | 550-1250 mm |

| Production speed | 20-120 pcs /min |

| Bag Height | 200-580 mm |

| Bag Width | 100-800 mm |

| Material basis weight | 30-120g/m2 |

| Power supply | 220v |

| Total Power | 15kw |

| Overall size | 11000X1900X2100mm(LX W X H) |

| weight | 2800KG |

Machine construction:

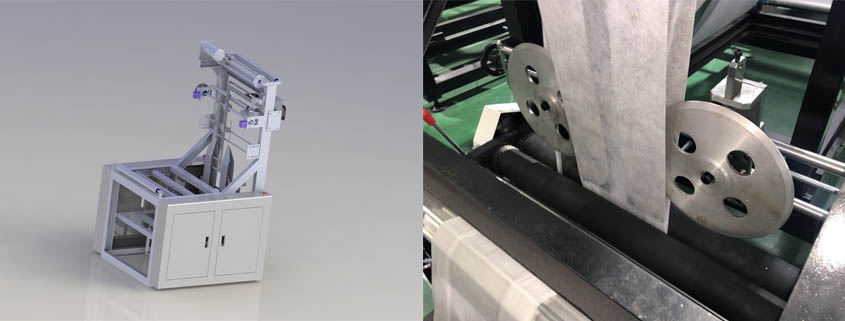

1. Feeding part

The maximum unwinding diameter of this machine is 1 meters.

Adopt automatic feeding, automatic tension, automatic photoelectric rectification, no stop machine and other industrial control devices.

Ultrasonic folding device: hand wheel, screw rod adjustment, ultrasonic welding.

The maximum diameter of the roll is 1 meters.

Main motor 1.5 KW

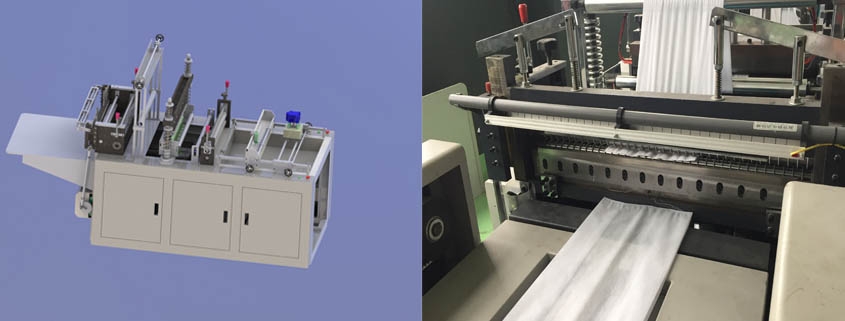

2. Fabric cross folding

The cloth is folded in half, the solid triangle steel frame, the non-woven cloth bag folded function, the adjustment is convenient, the whole equipment does not move the situation, also may straighten the material.

3. Vest bag insert part

70 mm one set ultrasonic for side sealing

Disk insert

It is suitable for flat bottom pocket, vest bag inserting edge, step motor to pull that long

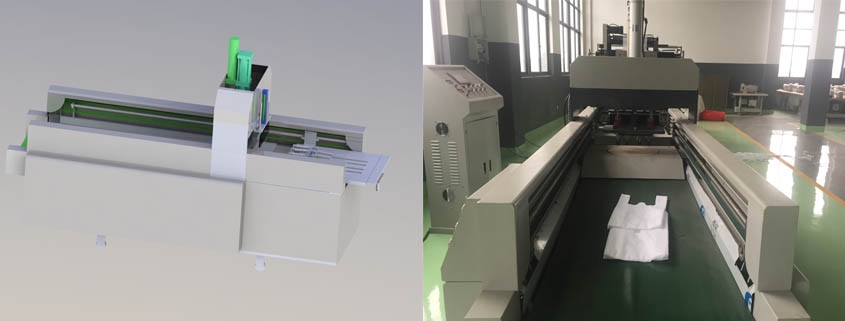

4. Machine head collecting bag

- The color recognition is high and there are basically zero errors.

- Automatically identify materials. When there is a shortage of materials, the ultrasonic non-woven machine automatically stops running.

- The edge is very strong and can be provided in different configurations according to different needs.

5. Automatic punching part

Clamping bag, mould stamping into vest ba

6. Distribution box

Touch screen control, easy to learn and easy to maintain

The machine configuration

| Feeding device | 1set |

| Folding and traction device | 1set |

| Vertical folding device | 1set |

Feeding device

| unwinding method | Magnetic powder tension control |

| Clamping device | Inflatable shaft φ3″(φ76mm) |

| Unwinding diameter | φ1000mm |

Control device and unwinding device

| Clamping device | Inflatable shaft φ3″(φ76mm) |

| Correction device | Use automatic correction system |

| Automatic stop without material | Using automatic travel switch stop material ,high precision |

| Feeding board | Stainless steel board(triangle) |

| Electric control system | Non-woven bag(two drive bag) making system |

| Ultrasonic system | 300 mm 2pcs 2500W,(Taiwan Ming you)

70 mm 3pcs 1500W,(Wenzhou Zhengxin) |

| Temperature control system | Temperature control components 1pcs |

| Operation method | The man-machine touch |

| Relay | Schneider |

| Pneumatic element | AirTAC (Taiwan) |

Commonly used appliances brand

| Temperature displayer | CHINT temperature meter, show preheat roll surface temperature |

| Commonly electrical components/switch | CHINT |

| Frequency converter | DEVER (Taizhou) |

| Frequency motor | Dott (Taiwan) |

Others

| Screen | Weinview (Taiwan) (LCD touch screen)built-in PLC |