Why do potato chips manufacturers fill the packet of chips with nitrogen gas?

Why do potato chips manufacturers fill the packet of chips with nitrogen gas? Filling the potato chip packaging bag with nitrogen is mainly for anti-corrosion and protection. Foods that are less prone to deformation are usually preserved by vacuum processing.

Others, such as the potato chips we eat, and those that are very brittle and easily deformed or damaged by extrusion, are usually filled with nitrogen gas. The nitrogen content in the air is very high. Let’s analyze it.

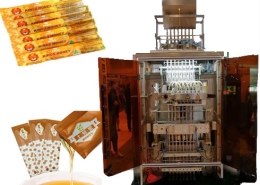

Potato chips are fried foods that contain a lot of fat and protein. Potato chip is made by chip packing machine.Many potato chip manufacturers are paying close attention to preventing crispy potato chips.

If potato chips are exposed to oxygen for a long time, a large amount of fatty acids in them will be oxidized, giving off a foul smell usually called “saliva smell”. In addition, the moisture in the air not only makes the potato chips moist, but is also very conducive to the growth of bacteria.

Therefore, potato chips must undergo a nitrogen flushing process during the packaging process. A 1994 study also proved that this method can maintain crispness and fresh taste.

This does provide a buffer and helps the potato chips adapt to changes in air pressure. In order to avoid consumer misunderstanding, the quality supervision department requires that the net content of all foods in the inflatable packaging must be stated.

Unfortunately, humans are not born with intuitive concepts of mass or volume. Therefore, no matter how obvious the number is, the vast majority of people will still open too few packages.

Food storage and transportation are important things that a food company should pay attention to. If the food is not well preserved or transported, there is a great possibility that the product will be damaged or even lead to food corruption.

This is not allowed. of. If the product cannot be transported and packaged well, it will have a very bad impact on the market. Therefore, a good packaging determines whether a product is qualified or not.

The main purpose of the enterprise by injecting nitrogen or sucking off the gas in the packaging is to ensure the freshness and quality of the food.

In order to ensure that potato chips are not easily oxidized or crushed, potato chip manufacturers use nitrogen to fill the inside of the package, that is, a package filled with nitrogen, and rely on inert gas such as nitrogen to prevent the presence of oxygen in the package.

If the packaging materials used for potato chips have poor nitrogen barrier properties, or the packaging of potato chips is not tightly sealed, the nitrogen or oxygen content in the packaging is likely to change, making the nitrogen-filled packaging unable to protect the potato chips.

Although the nitrogen content in the air is as high as about 70%, the remaining 21% oxygen will oxidize the food. Filling the potato chip packaging bag with nitrogen is a very good choice, which not only guarantees the shape and appearance of the potato chips. ,

And it can also ensure a low-oxygen environment for potato chips, so as not to deteriorate due to oxygen. The content of nitrogen in the atmosphere is very high, and it is also a very good low-cost protective gas.

This method is very suitable for the storage, transportation and quality assurance of potato chips. Nitrogen is non-toxic and harmless to the human body, so it is used as a good food protection gas.

The mixing of nitrogen, oxygen and other rare gases in the air can easily lead to food corruption. Therefore, many companies use vacuum packaging or nitrogen-filled packaging. These methods can guarantee the quality of food.

The shelf life also brings great convenience to transportation. At the same time, we also want to thank those manufacturers who provide us with convenient services.

FAQ

Is oxygen used in potato chip bags?

There is no oxygen in the potato chip bag. Oxygen is prone to oxidative reaction with food, which will deteriorate the quality of potato chips and lead to the reproduction of microorganisms.

Is it the least suitable to be filled with oxygen or air in food packaging bags such as potato chips?

Both are not good, and it is still not suitable for flushing by comparison.

Because there is everything in the air, including dust, impurities, bacteria, etc.

Oxygen is not good, which can easily cause food to rot.

In fact, it is generally filled with nitrogen. Anti-corrosion, sanitation, and low cost.

Related products

Contact us

0086 133 0206 3626(Mobile)

0086 22 68587918

enquiry@chinashrinkmachine.com

SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN

SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN