How to package granola bars or chocolate bars to sell?

Granola bars or chocolate bars is a kind of instant food, because oats have the effect of lowering blood fat, lowering blood sugar and high satiety, it is one type of pillow packing machine.It is widely used in chocolate bar wrapping, protein bar packaging, energy bar packaging,cereal bar sealing and so on.

The first thing you need to consider is how you are going to package your granola bars for sale. Different kinds of oats have different shelf-life and should be stored in a cool, dry place. Most oat bars can remain fresh for six to eight months if stored properly. Be sure to leave the lid on your oat bars once they are opened, as they should be consumed within two weeks of being made.

But do you know how to package granola bars to sell?

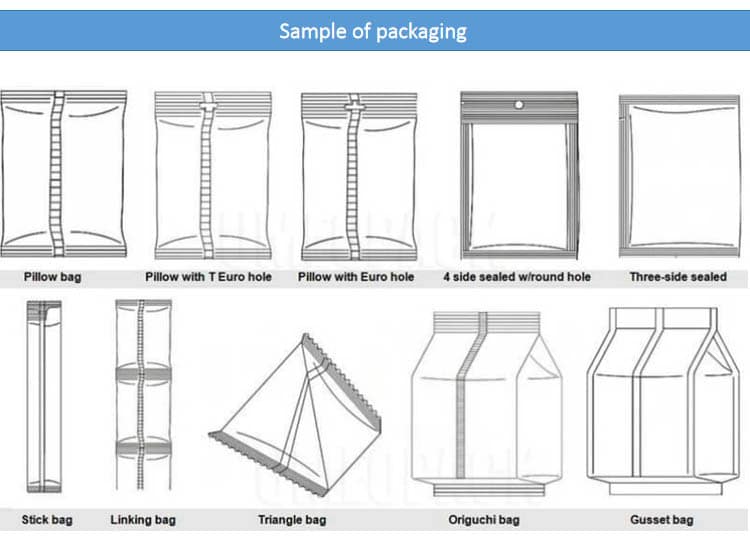

#1. First choice:Yes, we need granola bar packaging machine.The most popular packaging design is back sealing bag.

#2.second choice: plastic wrap or tinfoil

Let’s discuss it.

#1. First choice:Yes, we need granola bar packaging machine.The most popular packaging design is back sealing bag.

To make packaging for oat bars easier, you can purchase a granola bar packaging machine. These machines are specifically designed for the packaging of oats. They use a motor to move the granola bars from one position to another. The machine uses a photoelectric tracking color code to monitor each oat bar while it packs each bar. Then the final product will be out of the conveyor belt.

Videos For How To Use Powder Packaging Machine

Features for granola bar or chocolate bar packaging machine:

1.The granola bar packing machine adopts touch screen control, the main control circuit adopts intelligent chip, metering, automatic detection of electrical fault, operation Simple, easy to adjust.

2.High-quality double frequency conversion simple mechanical structure, easy maintenance, less wear and tear, long life.

3.High-precision photoelectric detection tracking, two-way automatic compensation, reliable.

4.Bag length does not need to be set manually, it is automatically detected and set automatically during the operation of the equipment.

5.Packing speed and bag length are controlled by double frequency converters, with infinitely variable speed and wide range of arbitrary adjustment, which can be perfectly matched with the previous process of production line.

6.Adjustable end seal structure makes the sealing more perfect and excludes the phenomenon of bag cutting.

7.Conveyor table surface stainless steel, the main part of the spray plastic baking paint treatment. Also can be made into full stainless steel according to customer’s demand.

Granola bar it is loved by many consumers, and even many ladies who lose weight use granola bars as a diet food.With the development of the economy and the improvement of consumption levels, the demand for oatmeal crisp quantity and quality continues to increase. Bagged granola is convenient and hygienic, and is becoming increasingly popular among the public.

#2.second choice: plastic wrap or tinfoil

Once you have made your oats and granola bars, you will need to wrap them in attractive wrappers and place them in an airtight container. Then, you’ll need to wrap them in plastic wrap or tinfoil. Once you’ve wrapped them, you’ll want to store them in an airtight container. You can make these packaging materials look like candy and even customize them for a personal touch.

Once you have your oats and granola bars wrapped in foil or wax paper, it’s time to package them. The most common way to package oats and oat bars is to use a granola bar packing machine. This type of packaging machine is specifically designed for granola bars, so you’ll want to get a special model for this purpose. Once you have a granola bar packing machine, you’ll be able to place your oats into it. Then, you can load them onto the conveyor belt. Once the oats are packed into the film, a transverse sealing cutter will seal the package. The finished product will be discharged by the conveyor belt.

Related products

0086 133 0206 3626(Mobile)

0086 22 68587918

enquiry@chinashrinkmachine.com

SHUNTIAN

SHUNTIAN

SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN