Automatic Case/Carton Erector STK-40

- Origin:Tianjin, China

- Model:STK-40

- Price Terms: FOB, CIF, CFR

- After-sales Service:Engineers available to service machinery overseas

- Payment:T/T,L/C

- Box Erector Manufacturer

- Vertical storage cardboard method

- Replenish the carton at any time

- Suitable for various sizes of cartons

- The rational design of the bottom sealing machine, synchronous absorption and forming

- Stable operation, long life, high efficiency

- 16-18 case/minutes

High Speed Case/Carton Erector

- Origin:Tianjin, China

- Model:STK-40H30

- Brand Name:SHUNTIAN

- Certification:ISO

- Payment:T/T,L/C

- Case/Carton Erector Factory

- Combination control of cam drive system and connecting rod

- Automatic warning reminder to replenish the carton

- Small footprint and high efficiency

- With or without tape automatic alarm function

- According to the thickness of the cartons, 80-90 cartons can be placed at a time.

The carton erector has a side-feed mechanism so that the machine can load more flat boxes without disrupting its production. The case erector can also be adjusted for different-sized boxes in less than 2 minutes.

What is case erector?

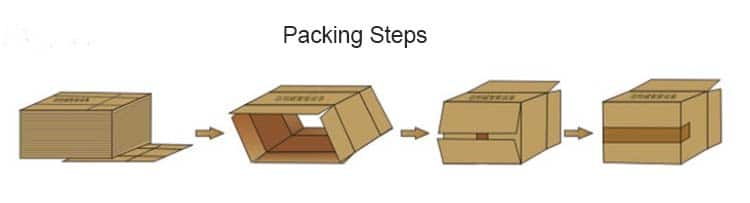

A carton erector machine is an automated device that automatically opens and folds cardboard boxes and seals the bottom and sides with tape.

These devices are commonly used in assembly line equipment, but they can also be used independently. A robotic hand attached to the machine ties up many cartons with tape.

A large number of such devices can be installed at once. These devices are an excellent choice for large-scale manufacturing. They can save both time and money.

The case erector is a machine that builds up a squared box. It seals the bottom and corners of the box, and the case erectors can even assemble used or recycled boxes.

The fully-automated model has a high production capacity and is ideal for medium-scale businesses. It can also assemble flat boxes that are used or recycled. So, if you’re looking for a reliable and efficient carton erecting machine, this is the one for you.

Fob Price:$4500-$8500

What is the feature for automatic box erector?

- One of the most notable benefits of a carton erector machine is its speed. This machine can easily form up to 12 boxes per minute in its vertical opening mode.The maximum speed is about five times higher than a human worker.

- The performance of the machine parts is precise and durable, there is no vibration in the operation process, and the operation is stable and has a long life;

- This case forming machine adopts PLC+human-machine interface display screen control, with high performance, high speed and high efficiency;

It can be operated as a stand-alone machine or used in conjunction with an automated packaging line.

Advantage of automatic carton erector?

Manual carton erector is also a simple packaging method, mainly the back-packing assembly line. Everyone needs to be responsible for different positions, but the work efficiency cannot be compared with automated unpacking.

The company has limited human resources and manual The cost is increasing every year. With the continuous acceleration of the development of factories and enterprises, such manual speed can no longer meet the needs of enterprises.

Therefore, the fully automatic carton erector appears in the new resources of the enterprise. It is not only fast and convenient, but also The main thing is that it does not require much human resources, and one machine can handle 3~5 manual labors, which greatly reduces the waste of human resources by the manufacturer.

The carton erector’s flexibility and ease of use make it an ideal choice for any production line. The advantages it offers make it worth investing in.

- It is an ideal piece of equipment for large-scale packaging.

- When compared to a human employee, a carton forming machine can produce 9600 boxes in one shift. The speed of an carton erector is comparable to a person’s eight-hour shift.

- Unlike manual workers, the machine does not need training to operate it.

- It also allows you to run it on its own while improving your efficiency.

- Option device is case sealer,which can ensure a safe load.

- The equipment is simple to operate and easy to maintain.

The case-erecting machine is an automatic carton erector machine that helps make square corners. This is important when stacking and palletizing boxes.

It not only provides a strong base, but also ensures proper weight distribution, which reduces the risk of loads collapsing.

A case erecting machine is an essential piece of equipment for any packing facility. Its precision and durability will last for many years.

How to maintain carton erector?

The air-controlled original part is an important structural part for of the automatic box erector, so the maintenance of the air-controlled original part is very important.

In various composition structures, the cost of this part is one of the high parts, we must be careful to understand the composition of the original part of the air control. It is specifically composed of the vacuum generator, the cylinder for taking the box, the cylinder for pushing the box, the front cover, the rear cover, and the cylinder for folding side covers. The detailed maintenance methods are as follows Six points:

1: If the air pressure pipeline needs to be disassembled for maintenance, when you want to install it back in position, you must pay attention to whether the oxygen tube has a broken tube. If this situation occurs, please guide it quickly to prevent air blocking.

2: The pressure setting should be appropriate and meet the requirements, so that it has sufficient air source capacity and ensure that the components operate

3: The pneumatic cylinder should be cleaned frequently on its moving shaft to prevent dust from penetrating into the piston and causing air leakage.

4: Keep the suction cup clean to avoid sticking to oil stains. The vacuum generator must be cleaned once a week.

5: the cleanliness of the air source, this is a very important point, so the air source must be kept clean at all times.

6: During shutdown or maintenance operations, use the pressure relief valve to discharge the residual air in the circuit

7: Lubrication: Check the lubrication levels and keep the machine well-oiled to avoid friction, rust, and wear and tear on the moving parts.

8:Belt and chain tension: Check the tension of the belts and chains to ensure that they are tight and properly aligned. Loose or misaligned belts and chains can cause the machine to malfunction or produce poorly formed boxes.

9:Peplace worn parts: Replace any worn parts such as belts, chains, motors, and bearings to ensure that the machine operates efficiently and safely.

10:Adjustments and calibration: Make adjustments and calibrate the machine regularly to ensure that it produces boxes of the correct size, shape, and quality.

Operator training: Train the operators on how to properly use and maintain the machine to avoid unnecessary wear and tear, breakdowns, and costly repairs.

By following these maintenance tips, you can extend the life of your case erector and ensure that it operates efficiently, which will help to reduce downtime and maintenance costs in the long run.

Related pages

Contact us

0086 133 0206 3626(Mobile) enquiry@chinashrinkmachine.com

SHUNTIAN

SHUNTIAN