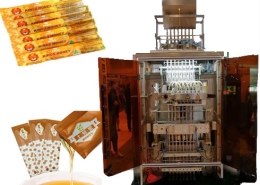

Application for multi line powder packing machine

The powder multi line stick machine is suitable for automatic packaging of chemical seasoning, milk powder, meal replacement powder,soy flour and other powdery materials, such as ultra- fine powder, broken wall pine pollen, barley leaf powder, meal replacement fruit and vegetable powder And other foods and pharmaceutical powder.

Technical Parameters for multi line powder stick packing machine:

| Model |

HY- F6 |

| Maximum packaging width |

900 mm |

| Vertical lines number |

4-15 lines, based on bag width |

| Packing Speed |

N*(20-45) N means lines |

| Bag length range |

80-180 mm |

| Bag width range |

20-50 mm |

| Filling range |

1-50ml |

| Sealing methods |

Pillow sealing, customized accepted |

| Power |

380v 50Hz 9Kw |

| Compressor |

0.8Mpa 0.7 m³/min |

| Packing material |

0.07-0.08 mm, OD less than 300 mm, ID 75 mm PET/AL/PE |

| Overall dimension |

1900*1880*2900 |

| Weight |

1980Kg |

Features for mulit line powder sachet packing machine:

1. Design the applicable silo according to the material status. Servo motor drive, longitudinal stirring and horizontal splitting, can be filled with nitrogen or exhaust.

2. Front and rear snap-fit longitudinal sealing mechanism, reciprocating transverse sealing film system, servo motor drive feeder, laser marking machine, etc.

3. The sealing mechanism is separated from the easy- to -tear device, which is easier to disassemble and replace and adjust.

4. The cutter adopts modular design, adopts imported materials, nigh precision processing requirements, wear resistance.

5. The equipment uses a multi- channel cooling mechanism to ensure that the cut s clean and that without burrs.

6. Automatic tension control of the film-covering mechanism, automatic correction, and automatic adaptation to the speed of the whole machine to ensure the strict operation of each process.

7. Independent temperature control mechanism, directly interact with PLC to ensure accurate temperature control.

8. Internationally renowned brand electrical components to ensure the stability and reliability of the control system.

9. Optional colour belt coding machine, vacuum feeder, laser marking machine, etc.

SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN