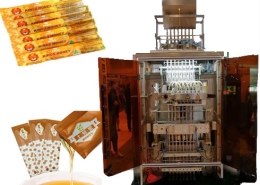

Best sachets packaging machines for sale

SHUNTIAN has 20 years of experience in the sachet packing field. We are a Chinese sachets packaging machines manufacturer.

These products are widely used in powder, granule, flake, liquid, sauce and other fields.

What is sachet packaging? What is sachet packaging machine?

What is a sachet packaging machine? A sachet packaging machine is an automated machine that packages a product with one or more layers. These sachets are usually made from a plastic material that can be folded into small rectangles.

These sachet pack machines are used to pack a variety of products that all have similar properties. They use a variety of sealers to prevent contamination.

They may be used to package pastes, liquids, or powders. The same machine can be used for different types of sachets. To understand how this machine works, consider some of the different types of sachets.

These machines can be customized to fit the needs of different industries. For example, they can pack instant soups, tea bags, and ketchups, harga bread improver and so on.

How are sachets filled?

A sachet packaging machine uses a forming tube to make a sachet. These sachets can be different lengths and widths. The sealing jaws move the film from the reel to the forming zone. The forming tube presses and seals the base and converging ends of the sachet. Finally, the sachet film is inserted and wrapped around the forming tube.

Videos For How To Use Sachet Packaging Machine

Sachet packing machine with string and tag

Three side liquid sachet packing machine

Back seal sachet packing machine

Multi does sachet filling and packing machine

Twins bag sachet packaging machine

Features for sachets packaging machine

Single-lane sachet packaging machines produce a single long pack that is then cut into individual sachets. Multi-lane sachet packing machines have multiple lanes, and can produce single-lane or multi-track sachets. In addition to sachets, sachet packaging machines can also create flat-bottom, pillow, and center-seal sachets.

A sachet packaging machine is usually an automatic machine that produces square or rectangular sachets. It can be used to package a variety of products. Its flexibility allows it to be used in a wide range of industries. The sachet packaging machine can also be used to package free-flowing liquids and pastes. The sachet packaging machine can be fully automated or semi-automatic.

A sachet packaging machine is a machine that creates single-dosed pouches by sealing the bottom of the sachet. It can be a horizontal sachet packaging machine or a vertical sachet packaging machine. The sachet packaging machines are designed to fit the needs of a variety of industries and are often programmed by hand. If you are unsure about which type of sachet packaging is right for you, our engineers can help you find the best sachet machines for your company.

Types of sachet packaging machines

1. According to the degree of mechanization, it can be divided into automatic sachet packaging machine and semi automatic packaging machine.

2. According to the film processing method, it can be divided into three side seal sachet packing, four side seal sachet, back seal sachet, continuous sachet sachet. You can see the difference between videos.

3. According to the state of the object, it can be divided into powder sachet packing machine, spices sachet packing machine, granules sachet packing machine, liquid and pastes sachet packing machine.

4. According to the packing size, it can be divided into normal sachet and mini sachet pouch packing machine.

5. According to the running channel of the packaging, it can be divided into single line sachet packing machine and multilane sachet pack machine.

6. According to the working mode of the machine, it can be divided into vertical sachet packing machine and horizontal sachet packing machine.

Advantage of using the sachet packing machine

1.The automatic sachet equipment can be designed for food, liquid, and semi-liquid products.

2.Its size is completely adjustable, allowing for different products to be packed in different sizes.

3.The biggest sachet packaging machine will pack sachets that are 40mm in diameter by 200mm in length. These sachet machines are typically used for pharmaceuticals, as they are very effective and efficient. The technology is very versatile, making them ideal for a variety of applications.

4.They also come with unique self diagnostics features that enable them to run more efficiently and with less downtime.

5.This kind of small sachet packaging machine is ideal for production lines that require a high production rate but do not require the highest filling speed.

Sachet packaging machine, Shuntian – China Premier Supplier and Manufactuer

Frequently Asked Questions

How much does sachet packaging cost?

Many customers are interested in the price of the sachet packaging machine.

So, how much does it cost?

Depending on the product and configuration it varies, in general, one of the cheapest sachet packing machinery is the machine is 3400 usd. However, it has a relationship with your product, packaging weight, etc. Some highly automated sachet packaging enquipment to reach 10,000 usd.

If you add self-feeding devices, product conveying lines, etc., it may reach 30,000 usd or more. Of course, it has a close relationship with international exchange rates, shipping, etc.

If you want to buy a sachet machine, please contact: enquiry@chinashrinkmachine.com or Whatsapp/Tel:0086 139 2007 7206

Difference between single line and multiline sachet packing machines

What is the difference between auger dosing sachet machine and volumetric cup filler machine?

There are many differences between an auger sachet machine and a volumetric cup filler machine. While the latter is more efficient, the former has more drawbacks.

For example, an auger filler’s agitator is not suitable for a product that is free flowing. Another difference is the size of the auger tooling. For optimum filling, it should have three to four turns.

Both types are cheap to purchase and operate and are easy to maintain. However, a cup filler is best suited for free-flowing products, while an auger filler is suited for non-free-flowing powders.

This machine also requires a lot of maintenance and cleaning. An auger is passive and cannot ensure consistent filling, whereas a volumetric cup is active.

Difference between vertical sachet and horizontal sachet packing machine

If you are looking for a highly automatic and flexible packaging machine that can pack different products, a horizontal sachet packing machine is the best choice.

These machines have many advantages, and can be used in construction, agrochemical, and food industries. They have the ability to run up to 80 cycles in a minute, so they are a great choice for small and medium-sized companies.

The main difference between a horizontal sachet packing machine and a vertical sachet packing machine is the method of filling and sealing. Both machines can run several lanes and can be designed for different applications.

Some of the differences between horizontal and vertical sachet packing machines include the size of the hopper, the material that goes into the sachet, and the number of lines.

A horizontal sachet packing machine uses a rotary knife to fill the sachet. The vertical sachet packing machine utilizes flexible packaging materials.

The advantage of a horizontal sachet packing machine is that it can use a variety of filling materials. As the film web moves horizontally, it seals one side while the other side is pressed closed.

Can aluminum foil be used for sachet packaging machines?

Yes, it can be used for sachet packaging machines.

What to consider when choosing a sachet packing machine?

Budget

The budget is the basis for purchasing something, not that the higher the budget the better, nor the lower the better. Instead, choose the most cost-effective sachet packing machinery according to your ability.

Product type

Different sachet packing machines are designed to handle different types of products. One machine can be designed for packaging powders and other similar products. Another model may be more appropriate for liquids or pastes. It is important to choose the right machine according to your needs.

Expert advice

It is difficult to get an objective opinion without visiting the factory. It is always better to seek advice from independent technical consultants whose expertise is specific to your product. This will give you an idea of which features to look for.

Where to find sachet packaging machines factories in China?

China is a very large country with many machinery manufacturers.

Shuntian has excellent achievements in this area and has gone to the leading industry of sachet packakging machines in China.

If interested, you can email or call us for more information.

Customers say

I am a small business that makes honey, and sachet type honey is very popular right now. I saw from a local family that they had bought a Shuntian sachet machine and it looked like it was performing quite well. I also purchased one and have been using it for almost a year now and the machine is very stable. Stability is the first thing we choose.

At first I bought a sugar sachet packaging machinery.Shuntian is a good sachet packaging machine factory. The output of this machine is 80 bags per minute. This kind of sachet packaging is very popular at present. The service of Shuntian is not bad, so we bought 4 more machines to expand our production.

I have a cafe and some customers think our coffee is pretty good and want to buy some back to drink at home. To make the packaging nice and easy to use, we came across Shuntian’s sachet packing equipment from Google.Wendy is very helpful for us. From buying advice to after-sales she did a great job and now we sell over 300 bags of coffee every month. This has increased our revenue.

Our restaurant previously used large cans of tomato sauce, which were very inconvenient to access each time and made the table very dirty. In order to facilitate single use, we introduced small bags of tomato sauce, which not only kept the countertop clean but also avoided waste. At first we didn’t know how to use the machine and Sara guided us with videos. Now it’s easy for us to pack the ketchup with just a push of a button.

Related products

0086 133 0206 3626(Mobile)

0086 22 68587918

enquiry@chinashrinkmachine.com

SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN