SHUNTIAN

SHUNTIANIntegral Type Fully Automatic Sleeve Sealer & Shrink Tunnel

Fully-auto Sleeve Sealer & Shrink Tunnel (Integral Type) STF-6030AH+STS-6040E

- Origin:Tianjin,China

- Certificate:ISO9001

- Price terms: FOB, CIF, CFR

- Payment terms:T/T, L/C

- Min order: 1 set

| Model | STF-6030AH | STS-6040E |

| Power | 1.8kw AC220V | 18kw AC380/220V |

| Tunnel Size | / | 1800*600*400mm |

| Packaging Speed | 12m/min | 0-20m/min |

| Packaging Size | 1428*900*1963(2100*455*760mm) | 2850*1000*1900mm |

| Machine Size | 2875*1378*1813mm | 2800*950*1750mm |

| Shrink Film | PE | PE |

| Weight | 620kgs | 625kgs |

STF-6030A + STS-6040E Fully-auto Sleeve Sealer& Shrink Tunnel is designed for a single object or objects with paper tray. This shrink wrap machine can be connected with other production machines with the function of automatically feeding, wrapping, sealing, shrinking and cooling, unmanned assembly-line to realize unmanned operation.

- STF-6030A introduces internationally advanced technology and production process which can automatically calculate the daily output; The performance is reliable;

- Induction film-feeding greatly reduces film waste;

- Imported digital temperature controller with precise temperature shows directly when it is sealing;

- Stainless mechanical speed adjustment device regulates the speed of the feeding conveyor;

- A specially designed three-piece sealing knife makes sure solid sealing line, no cracking and anti-stick;

- The usage of PLC and touch screen achieves the integration of mechanism, electricity and pneumatic;

- Feeding conveyor can be designed in the left side or right side as per your need;

- STS-6040E using imported double air circulation motors, so that the hot air in the oven can spread more evenly to get a good shrink effect;

- Large amount of cooling air flow, rapidly cooling the product after heat shrinking;

- The use of French Schneider frequency inverter controls transmission speed which has the function of infinitive speed;

- For drinks, beer, mineral water, cans, glass bottles with paper- tray and cardboard boxes integrated or single product’s shrink-wrapping.

Latest news

Contact us

0086 133 0206 3626(Mobile)

0086 22 68587918

enquiry@chinashrinkmachine.com

Cucumber Shrink Wrap Machine

Cucumber is a very common fruit, but in order to keep it fresh, a cucumber shrink wrap machine is generally used to shrink it. It is one of l sealer shrink wrap machine.

The cucumber shrink wrap machine consumes little power during operation, and can be operated continuously for a long time without causing the surrounding environment to become too hot.

Cucumber functions as a seal after shrink packaging by a heat shrink packaging machine. After sealing and cutting a variety of food packaging, the machine automatically transports it to the shrinking furnace through a belt.

The height of the conveyor belt can be adjusted to different heights. It is stable and reliable by compressed air. The seal is neat and does not coke or crack, and the product after shrink packaging is not only beautiful and generous, but also saves packaging costs. The machine has air-tightness, dust-proof, moisture-proof and other functions.

Cucumber shrink wrap machine accurately controls the sealing time through a time relay to improve the quality of the sealing. The entire sealing action is controlled by pneumatics.

It is equipped with semi-automatic and automatic functions, which reduces the work intensity and improves the work efficiency.

The cucumber shrink wrap machine can be ordered according to the customer’s needs, and it can produce 10-60 pieces per minute. If calculated according to the working time of 8 hours per day, it will produce 28,800 pieces.

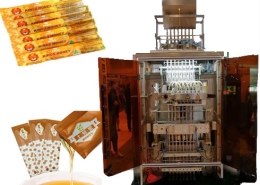

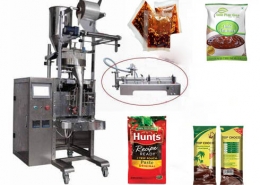

Commercial Honey Pouch Stick Filling And Pack Machine For Sale

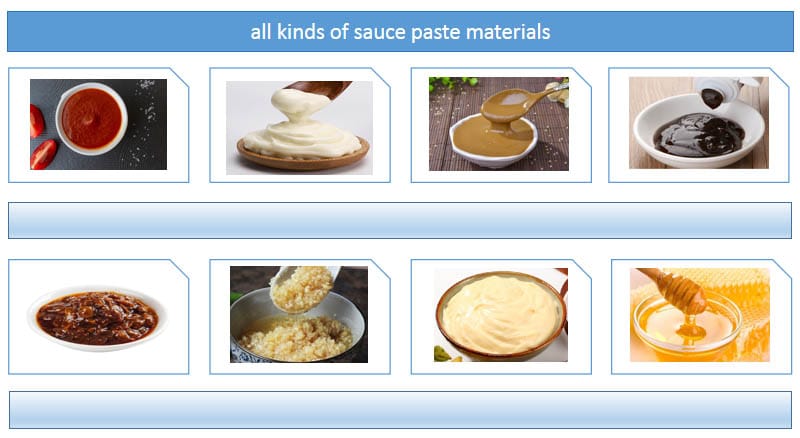

The commercial honey straw sachet filling machine is one type of stick packing machine. The honey pouch machine is not only fast in speed, but also stable in operation, which is especially suitable for honey, dipping sauce and silky crystalline paste, barbecue sauce, soy sauce, garlic chili sauce, spicy beef sauce, peanut sauce, tomato sauce.

Check out the following video on how to use Cucumber Shrink Wrap Machine is used

Check out this video on How To Use Commercial Honey Stick Packing Machine

Features for commercial honey straw pouch filling and packing machine

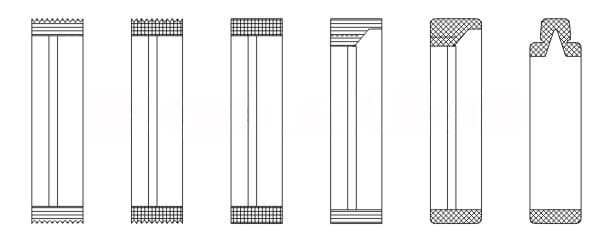

The honey stick packaging machine adopts three pairs of special drum-type sealing devices, and the sealing pattern adopts continuous checkerboard pattern home leak-proof line method (or line pattern method).

The whole honey stick filler includes: bag making, longitudinal sealing, filling, transverse sealing, transverse strengthening sealing, double easy-tear incision making, cutting, printing and other main processes.

The motor separately drives the vertical sealing, horizontal sealing, and cold horizontal sealing rollers, without chain transmission, which changes the inconvenience of manual adjustment of the third stage cold horizontal sealing in the current market.

The feeding device will be selected according to the physical condition of the hot-filled materials, including a magnetic pump (M) for liquid filling and sealing, a Haiba pump (H) for homogeneous sticky body filling, and a piston pump (P) for paste filling. Screw device for powder filling (O).

The cutting knife can use one of three methods: flat knife, sawtooth, and dot and dash, and the dot and dash knife is used to separate the bags between the two bags.

Applicable product packaging:

Pesticides: emulsifiable concentrates, liquids, microemulsions, additives, suspending agents, etc.

Food category: seasoning sauce, vinegar, soy sauce, honey, etc.

Daily chemicals: lotion, cream, etc.

Related technical parameters:

DXDY-500H

DXDY-800H

Sealing form for honey sachet bag:

Back seal/Three side seal

Packing speed 20-50 packs/min 20-50 packs/min

Maximum bag size 150mm*200mm 200mm*280mm

Measuring range 100-500ml 100-800ml

Power supply 220V 220V

Weight 350kg 400kg

Product specifications: 760mm*900mm*1850mm 1100mm*900mm*2000mm

The pouch honey packaging machine has been favored by many honey manufacturers since its launch. If you have a demand for a honey packaging machine, please contact our company. We have a professional sales customer service to plan and select the type for you. Contact:enquiry@chinashrinkmachine.com 0086 13920077206

Frequently Asked Questions

What are the factors that affect the efficiency of the honey sachet liquid packing machine?

There are many factors that affect the efficiency of honey sachet liquid packing machine, among which high temperature and humidity are the main factors.

Many parts of the honey pack packing machine are all made of metal composite materials, and some failures are inevitable. In order to avoid the use problems of these sauce packing machines, we need to choose as much as possible the filling machine that has been sealed and has the corresponding anti-corrosion ability.

The daily use of the honey sticks packaging machine requires regular maintenance of the equipment, checking the lubricating fluid of the equipment, whether there is corrosion and rust and other problems, all of which are part of the maintenance of the filling machine. If the user is far from mastering the machinery and equipment, please do not arbitrarily conduct equipment maintenance.

Everyone needs to check the operation of the honey stick bag packing machine from time to time. If there is noise or the operation is unstable, it is necessary to maintain the machine and equipment in time, and check whether the equipment power distribution line, parts and accessories fall off and whether the machine equipment is clean.

Due to some objective factors, the packing machine should be left unused for a long time. It is necessary to completely remove the residues inside the honey stick making machine, perform anti-rust treatment on the honey sticks machine, and cover the machine equipment with a moisture-proof cloth.

At present, there are many types of filling machines, and the types of filling materials and use efficiency are different. The actual filling and use are helpful to the selection of the packaging machine.

How to operate the honey stick packs packaging machine

1. Install the consumables: put the wrapping paper on the support rod, connect it to the former, and test whether the honey stick filling machine is normal.

2. Connect the organ: connect the honey stick bag machine, and the power supply is preferably connected to the wall socket.

3. Set the panel parameters: set the honey bag length and temperature parameters and the quantitative capacity of the filling machine.

4. Place the material: put the material in the liquid container and press start.

5. Automatic packaging: the honey stick filler machine automatically measures, blanks, and seals and packs in one time.

How to choose honey stick filling packing machine?

For materials such as honey that are viscous and easy to crystallize, it is recommended to use a non-drawing pouch honey stick bag packing and filling machine. The characteristics of this honey sachet packaging machine are high speed and stable operation.

It also has a double-layer insulation barrel, no matter what the season or the temperature. It can ensure the concentration and purity of the honey, and it also has a suction device to make the small bag of honey that does not contain materials and leaks.

This is a three-pair roller vertical packaging machine designed for automatic packaging of uniform viscous and paste materials such as shampoo, honey, syrup, etc.

It has fast packaging speed, flat bag shape, exquisite and beautiful appearance, and adopts advanced PLC plus photoelectric control system. It can be packaged with three-side sealing or four-side sealing.

What kind of material should I use to pack honey in a bag?

The following are the characteristics of various materials suitable for sachet packaging:

1. PE is suitable for low temperature use, and RCPP is suitable for high temperature cooking;

2. PA is to increase physical strength and puncture resistance;

3. AL aluminum foil is to increase barrier performance and shading ;

4. PET, increase the mechanical strength, excellent stiffness. Then according to the needs, combination, various properties, there are also transparent, in order to increase the barrier performance, use the water-resistant PVA high barrier coating.

What kind of honey is in honey sticks?

Jujube honey, sesame honey, wolfberry honey, rose honey, sweet-scented osmanthus honey, and all honey that can improve taste or increase efficacy can be made into honey sticks.

Customers say

We have used products from other suppliers and doesn’t work as well. Also we had a problem in the past, as we ordered a wrong product. We have a perfect solution from SHUNTIAN, we are very pleased with their service.

This was an excellent choice. After receiving the honey stick fillling sealer i was very impressed with how it works, i am amazed at how well it does its job, so much better than the clamp and seals style I’ve had for years. Definitely a great buy.

The honey stick machine is well constructed and looks impressive, The user manual is basic a video for the setup parameter would be helpful and or more setup detail in the user manual.

professional manufactory of packing machine,filling machine, sealing machine.

SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN

Shaped honey stick package