Model: STS-4525

Model: STF-20LG/B

Semi-auto L Bar Sealer Shrink Wrap Tunnel STF-20LG/B+STS-4525

- Origin:Tianjin,China

- Certificate:ISO9001

- Price terms: FOB, CIF, CFR

- Payment terms:T/T, L/C

- Min order: 1 set

0086 133 0206 3626(Mobile)

Check out this video on how our Semi-auto L Bar Sealer & Shrink Wrap Machine is used

| Model | STF-20LG/B | STS-4525 |

| Power | 1kw AC220V | 9kw AC380/220V |

| Tunnel Size | Air Source 6-8kg/cm² | 1000*450*250mm |

| Packaging Speed | 0-15m/min | 0-10m/min |

| Shrink Film | POF PVC | POF PVC |

| Machine Size | 1730*790*980mm | 1300*800*1520mm |

| Packaging Size | 1780*840*1130mm | 1350*850*1670mm |

| Weight | 155kgs | 270kgs |

Features for semi-automatic L bar shrink wrap machine

1、Adopting manual button type control and automatic sealing.

2、Programmable controller controls the whole set of actions, making the l sealer shrink wrap machine run more reliably.

3、Highly sensitive temperature controller combined with special treatment sealing and cutting knife, so that the temperature control is more accurate and sealing is more solid.

4、Adjustable film outlet combined with induction switch to control the length of the incoming film, so that the film can be thinner and less loss.

5、High-power turbo fan in the furnace body, so that the circulation air volume is more adequate.

6、Oversized fan cooling system outside the furnace, so that the package is set faster.

7, the heat shrink furnace lengthening, so that the speed can be faster, better shrinkage effect.

8、The heating tube is made of stainless steel, which makes the heat dissipation faster, saves electricity and has a long life of 5-10 years.

9、The conveyor chain adopts roller type, which makes the load bearing better and the life longer.

10、Conveyance adopts high power motor, infinitely adjustable speed, more stable conveyance.

11、The conveyor belt can be designed as Teflon mesh or stainless steel mesh chain according to customers’ special requirements.

How to improve the effect of the semi-automatic L bar shrink wrap machine?

Products often have to undergo several experiments to achieve an ideal result when shrinking. In order to avoid wasting time and maximize the shrinkage debugging time. Shuntian summed up some shrinkage tips to share with you:

1. shrink film material: even if the same type of shrink film, the quality is also distinguished, good shrink film stretching ratio of vertical and horizontal uniformity, when entering the shrink wrap packing machine film elongation rate of the same, the product shrinkage film covered equally on the product.

2. sealing treatment: shrink machine shrinkage before the product needs to be fully sealed in the bag. This requires sealing on all sides of the film. The thickness of the sealing line will be directly reflected in the appearance of the product. Customers can use the folded film with L-shaped sealing and cutting machine to use, sealing line with 1mm can.

3. film margin: this refers to the bag after the product is loaded empty, we often think that the smaller the margin of the packaging film before shrinkage, the better, in fact, it is not, the right margin will give the shrink film a space to expand up. Instead, the contraction effect is better.

4. film: I have seen many people do experiments, sealing and cutting directly into the shrink oven, shrink out very easy to appear fold zou, a good method of operation is to seal and cut the film first pull flat, it is best not to have fold zou, especially for small products packaging.

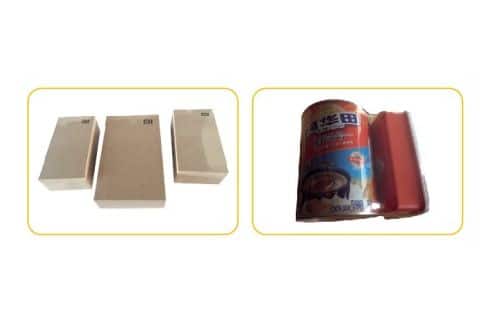

Related products

0086 133 0206 3626(Mobile)

0086 22 68587918

enquiry@chinashrinkmachine.com

SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN SHUNTIAN

SHUNTIAN shuntian

shuntian

SHUNTIAN

SHUNTIAN